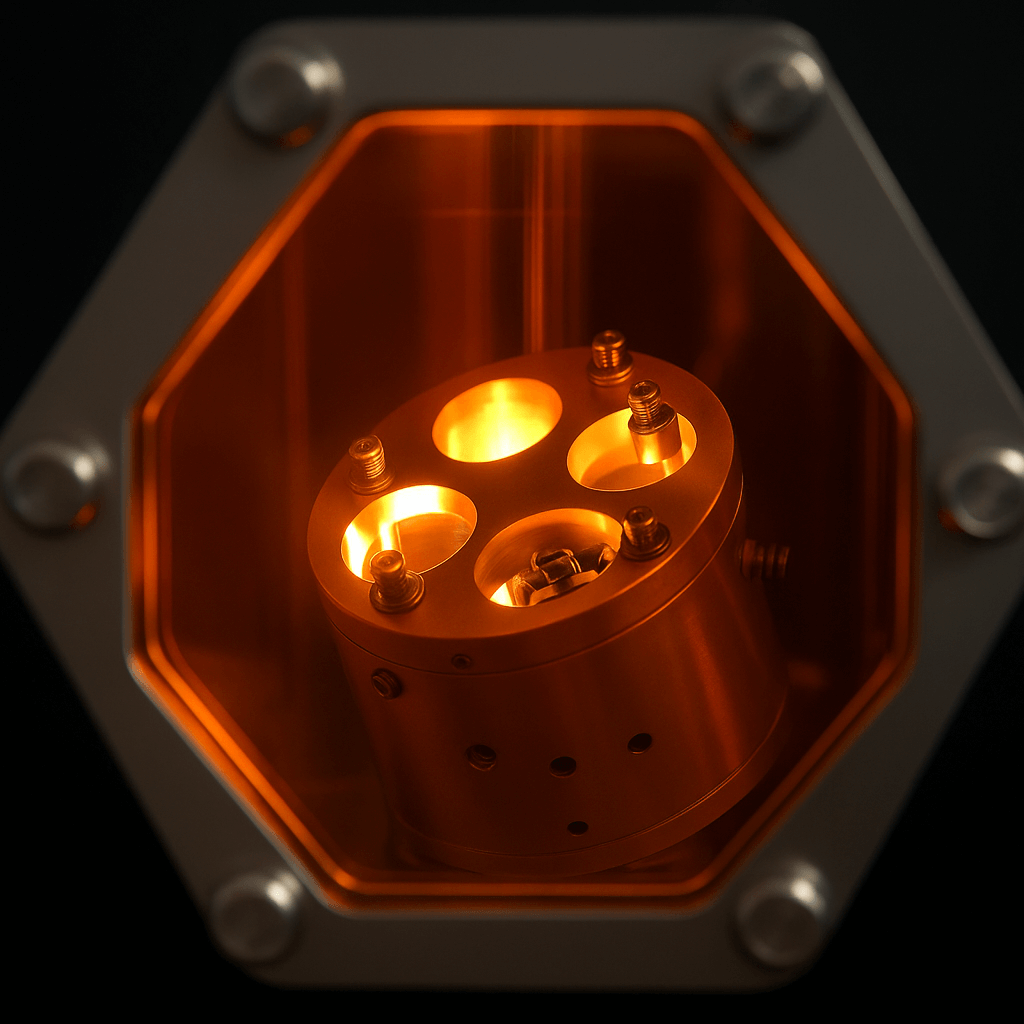

The E-Beam System has become a crucial technology in various industries that require high levels of cleanliness and safety. By using a concentrated beam of high-energy electrons, this system effectively sterilizes medical devices, pharmaceuticals, food packaging, and more. Its speed, efficiency, and non-thermal nature make it especially useful for materials sensitive to heat or chemicals.

How the E-Beam System works

The E-Beam System operates by generating a focused stream of electrons that penetrate materials at high speed. These electrons disrupt the DNA of microorganisms, such as bacteria, viruses, and fungi, rendering them inactive. Because the process takes place in a fraction of a second and does not require additional substances, it leaves no chemical residue and allows for immediate use of the treated product.

Applications in the medical and pharmaceutical sectors

Hospitals and pharmaceutical manufacturers depend on reliable sterilization methods to ensure patient safety and product integrity. The E-Beam System plays a significant role in sterilizing syringes, surgical tools, and sealed medication packaging. It allows for bulk processing with minimal handling and reduces the risk of contamination. Furthermore, its dry process supports the sterilization of moisture-sensitive materials like powders and polymers.

Advantages over traditional methods

Traditional sterilization methods, such as steam or ethylene oxide gas, involve longer processing times and potential compatibility issues with sensitive products. The E-Beam System offers a faster alternative that minimizes downtime and increases production output. Its ability to process products in their final packaging also reduces handling errors and supports tighter quality control.

Environmental and safety benefits

Unlike some chemical-based methods, the System does not produce toxic byproducts or require long aeration periods. It reduces water and energy consumption and lowers waste output, making it a more sustainable choice. Operators manage the system in shielded enclosures, ensuring safety while maintaining compliance with radiation protection regulations.

Use in food packaging and preservation

In the food industry, companies use the E-Beam System to extend shelf life and enhance food safety. It can sterilize packaging materials and even treat certain food items without affecting taste or texture. By reducing microbial contamination early in the production line, it helps prevent spoilage and supports global food distribution.

Innovation and future development

Researchers continue to explore how to expand the capabilities of the E-Beam System, including higher precision targeting and broader treatment applications. Innovations in beam control, shielding, and compact system design may soon allow for wider integration across different industries.

Conclusion: a growing industrial standard

The E-Beam System has earned its place as a reliable and efficient sterilization method in modern manufacturing. As industries prioritize both performance and sustainability, this technology will likely become even more widespread in the years to come.